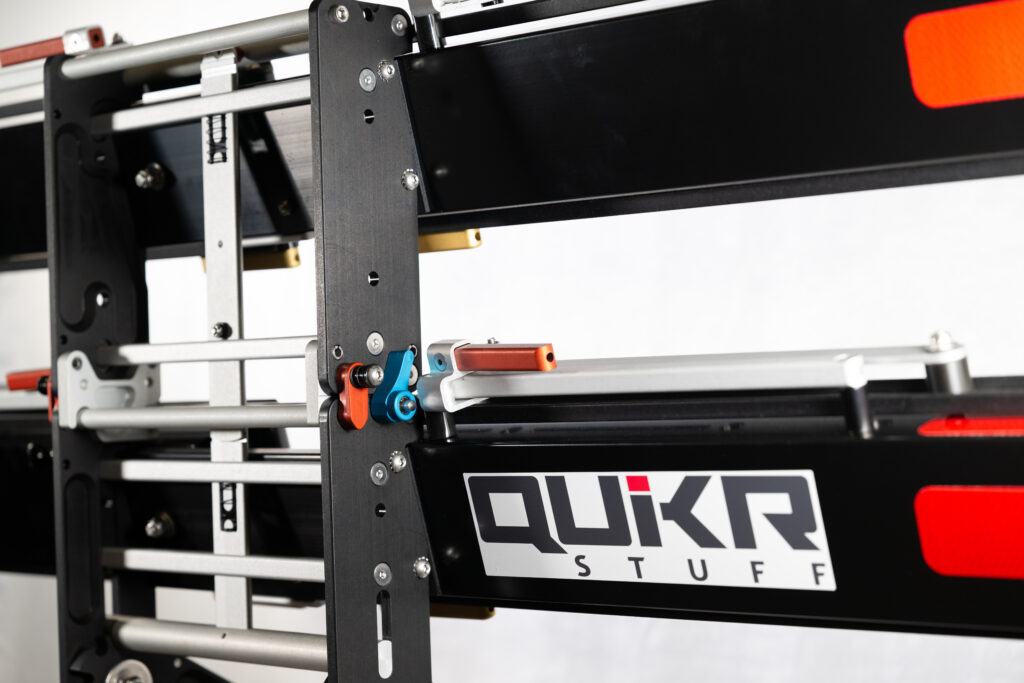

Made in the USA with Globally-Sourced Raw Materials

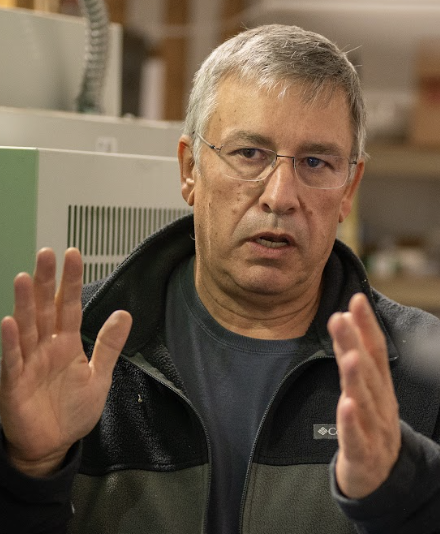

We are proud to manufacture and assemble our bike rack in the USA. In fact, even more than that, we strive to support businesses within our community. We have a robust network of local suppliers and manufactures. But the reality is that our rack is made from products that are sourced globally. In fact, when you really think about it, it’s almost impossible to make anything that is 100% made in your location, no matter where or what that is.

Think of that loaf of bread that you made. You probably didn’t grow the wheat. And you may not know where the wheat came from, where it was processed into flour or where it went for distribution. The fact is, these days, products come from everywhere and consist of things we don’t think about. The wheat may have been grown on a farm in Ukraine then shipped to Ohio where nutrients and bleaching agents were added and processed into flour. After that, it was probably shipped to a warehouse for distribution and eventually made it to your kitchen table, where you proudly said, “I made this bread right here in my kitchen.” Similarly, we purchase aluminum, cut the aluminum into parts, purchase nuts and bolts and then assemble everything into a pretty awesome bike rack. Then we boldly stamp it “Made in the USA,” which is true, though some of the components came from other countries.

From Aluminum to Extrusions: The Journey of Our Materials

Let’s drill down a little further and consider what we buy to produce our rack. We buy aluminum from vendors that obtain or extrude aluminum into shapes that make manufacturing easier and result in less waste. We call those shapes extrusions. Extrusions take the form of round bars, square bars, hexagonal bars and all sorts of proprietary shapes, like our wheel trays and pivot arms. These bars usually come to us in 12-20 foot lengths. The common extrusions like round-bar and square-bar come from distributors in Denver that deal in high usage shapes. Our proprietary extrusions, which are about 60% of the aluminum on our bike rack, are sourced directly from Bonnell Aluminum in Utah. Bonnell Aluminum is what we call an extruder. Geographically, they are closer to us than any other extruder; again, trying to keep it local. Despite their name, Bonnell Aluminum doesn’t actually make the aluminum. Like most extruders, Bonnell buys the aluminum in large blocks, called ingots. The ingots are purchased from smelters. We are not privy to the exact source of most ingots nor the location of the smelters, but it’s safe to say that Bonnell uses both foreign and domestic smelters. Bonnell heats the ingot to near molten metal, then presses it through a die that has the extrusion shape built in. It’s similar to how spaghetti is made (extruded), but, obviously, on a much larger scale.

Smelters: The Global Journey of Aluminum Production

So, what are smelters? Smelters are facilities where raw aluminum is made (not mined, but produced). As I alluded to earlier, we don’t get to choose the smelter. Additionally, even if we could choose a U.S. smelter, some may not consider the aluminum as made in the USA. Why is that? Because the bauxite ore from which aluminum comes was most likely mined somewhere other than the U.S. Plus, other elements–aluminum oxide, copper, magnesium, manganese, lithium and more–are commonly added to enhance the properties of aluminum for various applications. And these elements, as you may have guessed, are mined and sourced from all over the world.

So that’s just aluminum. Keep in mind that every single screw, washer or part has a similar story. It’s mind boggling. But all you really need to know is that the Quik Rack Mach2 bike rack is proudly manufactured and assembled in the USA.