Made in Grand Junction, CO, USA, EARTH

When quality and craftsmanship are of the utmost importance, look no further than your backyard! At QuikrStuff we support industry in rural Western Colorado and take pride in creating jobs in the USA. That’s why we design, manufacture, and assemble the Quik Rack Mach2 bike rack and accompanying products right here in Colorado. Our racks are tested and proven in our rugged Colorado and Utah backyards, so we know they’ll perform for you.

See some of our favorite rides from Grand Junction and beyond right here.

QuikrStuff was born in January of 2020, just two months before the COVID 19 pandemic hit. We pushed through the initial chaos and long aluminum lead times to deliver our first orders in August of 2020. Recently, our small but burgeoning company hit a new milestone–order #20,000! In celebration of this milestone, we want to share a little about how the QuikrStuff Mach2 is made.

Hand-built in Grand Junction, Colorado.

How It’s Made

The Mach2’s journey to your front door begins when aluminum stock is delivered to our machine shop and fabrication facility. Lean manufacturing and a passion for quality guide our process at every step.

Next, the aluminum makes its way through the machine shop. CNC mills, lathes, saws, and our crew of machinists quickly turn a pile of aluminum stock into functional components of the Mach2. If you walk into the shop, you’ll hear the sounds of milling and turning, and smell cutting fluid. Our seasoned machinists have an eye for the little details and a passion for quality. We run two production shifts per day so that your new rack lands on your doorstep as soon as possible.

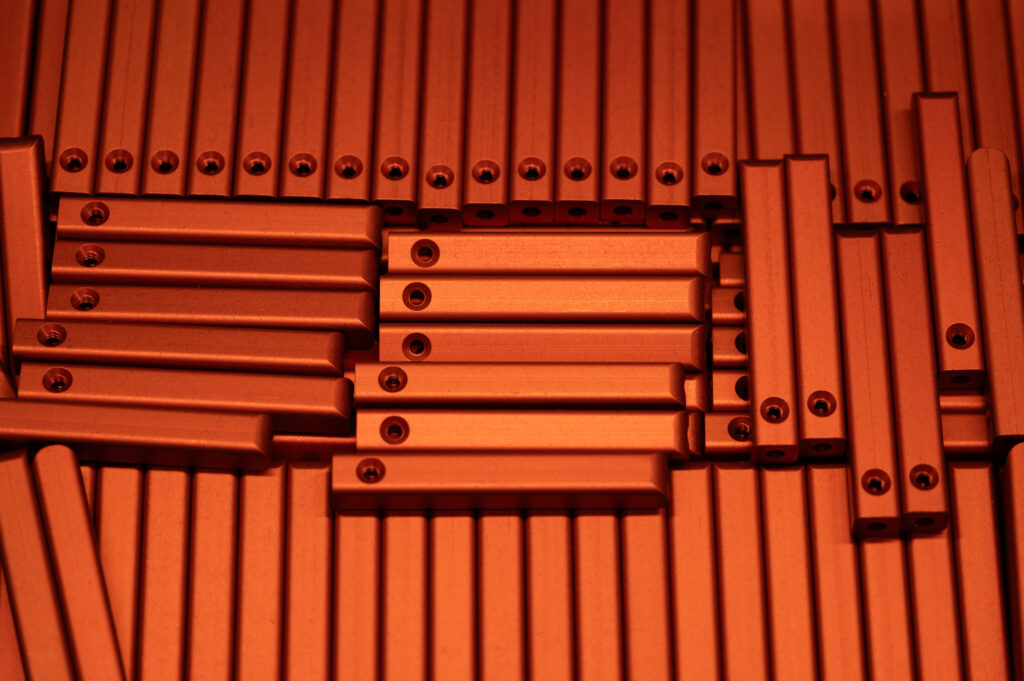

Once all of the parts have been machined, they move to the polishing stage. Almost all of our parts go through a tumbler to ensure a consistent surface finish. After that, some are sent off to be anodized. Aluminum anodizing is a finishing process that produces wear- and corrosion-resistant aluminum oxide coating on the surface of aluminum parts. This coating can be colored after anodizing for a decorative finish. Luckily, anodization is performed close by. Since transportation only takes a few minutes, this helps to shorten our lead times. How great it is that we can partner with other local businesses to support even more jobs in Western Colorado.

These parts are going through the final phase of anodizing.

Now, this pile of parts is starting to look a little more recognizable.

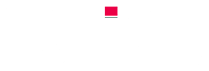

Our assembly technicians make quick work of turning this pile of machined parts into the best-looking bike rack on the market! With designated subassemblies, it is possible for our skilled assemblers to ensure that every operation is done with care and that all parts move smoothly and consistently.

At the final assembly step, the rack tray is mated to the hitch. Each half of the rack is torqued to ensure it pivots smoothly and easily. Each tray is adjusted so they readily snap into place when the rack is unfolded. Once everything is put together and the rack is checked for operability, it moves to the shipping area.

From here, we check the keying of the rack to ensure everything is correct. Did you know we key add-ons and other accessories to match the customer’s original rack? The Mach2 is truly a single-key system. Next, the racks are folded up and boxed for shipping. Here, we take great care to wrap the racks and pad them, so they arrive at your doorstep just how they left our factory. Throughout the day, the pile of boxes grows as we eagerly await FedEx to arrive for its daily pickup.

It is our pleasure to provide a great product made in the United States. We hope you enjoyed this brief tour of our operations.

Once your rack arrives and you have some time to get familiar with it, feel free to reach out to us or drop a review. We are always looking for feedback and ways to improve this product. Send any comments or suggestions to Support@Quikrstuff.com.